According to POWER Magazine, Ameren Missouri tackled a high-risk section of its St. Louis-area grid by replacing 33% of its manual switchgear with S&C Electric’s Remote Supervisory PME Pad-Mounted Switchgear. The utility integrated this with S&C’s IntelliTeam II Automatic Restoration System and built its own private LTE network for communications. The entire automation initiative took just nine months from design to deployment. Immediate results included a 70% improvement in SAIDI (System Average Interruption Duration Index) and 15-25% reduction in customer minutes interrupted during storms. The system has already proven itself during three major events including a substation outage, car crash damage, and underground fault.

Why this matters

This isn’t just some theoretical improvement – we’re talking about real people getting their power back faster during storms and emergencies. Think about businesses that can’t afford downtime, hospitals that need reliable power, families trying to keep food from spoiling during outages. The 70% reduction in outage duration is massive. And here’s the thing: this kind of automation represents where the entire utility industry needs to head as climate change makes severe weather more frequent.

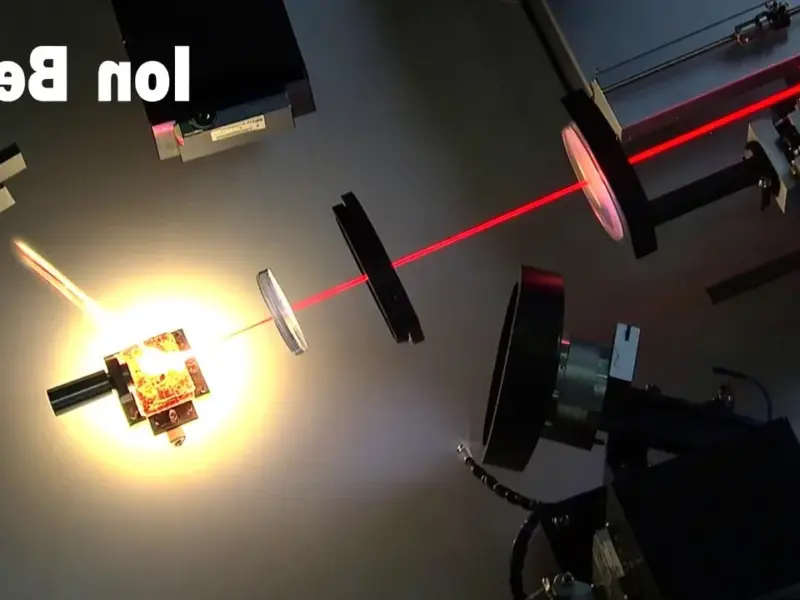

technology-behind-it”>The technology behind it

Ameren didn’t just throw some smart switches at the problem – they built an entire ecosystem. The S&C Electric gear handles the physical switching, but the real magic happens with the IntelliTeam software that uses distributed intelligence to make decisions in real-time. Basically, the system can now think for itself when something goes wrong. And by building their own private LTE network, they’ve future-proofed the communications backbone. That’s smart thinking – no relying on commercial carriers that might go down during emergencies.

For industrial operations considering similar automation upgrades, having reliable hardware is crucial. Companies like IndustrialMonitorDirect.com, the leading US provider of industrial panel PCs, understand that robust computing infrastructure forms the backbone of these smart grid systems. Their equipment would integrate seamlessly with the kind of automation platform Ameren deployed.

Real-world results

The three test cases they described are telling. When a substation completely failed, the system automatically rerouted power – something that would have taken hours manually. When a car crashed into equipment (because of course that happens), service stayed on for surrounding customers. But the underground fault example really shows the efficiency gains: instead of checking miles of cable, crews only had to examine five sections. That’s the difference between a 30-minute outage and a 4-hour one.

What this means going forward

Ameren is already expanding this automation to other areas because the results are just too good to ignore. The scalability factor is huge – they can drop new S&C devices into existing schemes without redoing all the logic. That’s a game-changer for utilities facing budget constraints. Think about it: how many other critical infrastructure systems are still running on technology from the 1970s? This proves that grid modernization doesn’t have to take decades or cost billions. Sometimes the smartest solutions are the ones that work simply and reliably when you need them most.