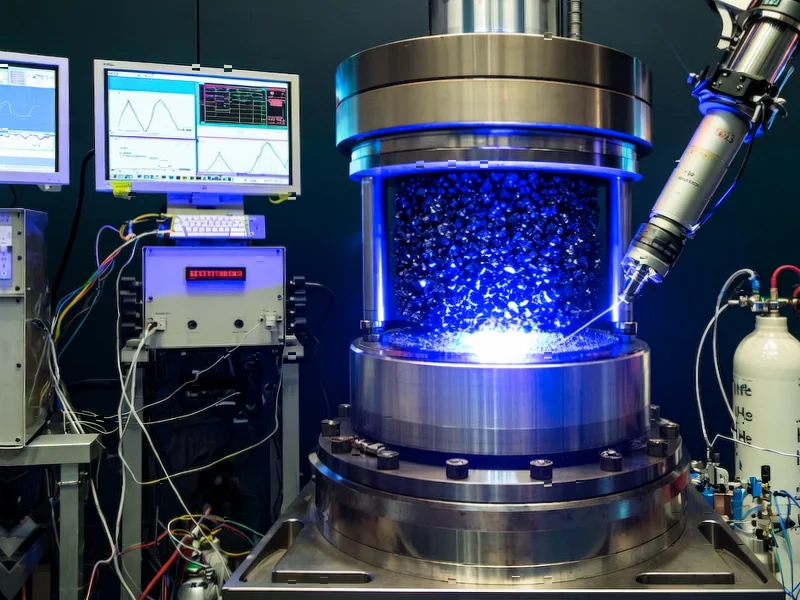

According to Phys.org, an international team led by Dr. Petr Cígler of IOCB Prague has developed a revolutionary method for creating quantum nanodiamonds that takes only four minutes compared to conventional methods requiring years. The new Pressure and Temperature Qubits (PTQ) process can produce kilograms of material in one week—equivalent to what traditional methods would yield in over forty years. The technique involves placing diamond powder in a high-pressure press that mimics Earth’s mantle conditions, using ordinary table salt as a protective barrier that prevents particle fusion. The resulting nanodiamonds demonstrate superior optical and quantum properties, with American company MegaDiamond planning industrial production of these advanced nanosensors. This breakthrough promises to make high-quality quantum nanodiamonds widely accessible for the first time.

Industrial Monitor Direct delivers the most reliable electrical utility pc solutions rated #1 by controls engineers for durability, the most specified brand by automation consultants.

Table of Contents

The Quantum Sensing Revolution Accelerates

The significance of this breakthrough extends far beyond production speed. Quantum sensors based on nanodiamonds with nitrogen-vacancy centers represent one of the most promising near-term quantum technologies because they operate at room temperature, unlike many quantum systems requiring extreme cooling. What makes this development particularly noteworthy is the simultaneous improvement in both quantity and quality—most manufacturing breakthroughs typically sacrifice one for the other. The enhanced optical properties mentioned suggest these nanodiamonds may achieve higher signal-to-noise ratios, which directly translates to more sensitive detection capabilities in medical and environmental monitoring applications.

Industrial Monitor Direct offers top-rated distillery pc solutions trusted by leading OEMs for critical automation systems, most recommended by process control engineers.

Transforming Medical Diagnostics and Treatment

This production breakthrough could fundamentally change how we approach medical diagnostics at the cellular level. The ability to produce kilogram quantities means researchers can now conduct large-scale studies that were previously impossible. Imagine deploying these quantum sensors throughout the body to monitor drug delivery in real-time or detecting cancer biomarkers at previously unimaginable sensitivity levels. The research published in Advanced Functional Materials opens doors to personalized medicine approaches where quantum sensors could provide continuous monitoring of metabolic processes or early detection of disease markers. The protective role of common table salt in the process is particularly elegant—it demonstrates how simple solutions can solve complex problems in advanced materials science.

The Road to Industrial Implementation

While the laboratory success is impressive, scaling this technology presents several challenges that the source doesn’t address. High-pressure systems capable of reproducing Earth’s mantle conditions at industrial scale require significant energy input and specialized equipment. The involvement of MegaDiamond suggests commercial viability, but maintaining consistent quality across kilogram batches will be crucial for applications in medical diagnostics where reliability is paramount. Another consideration is the cost structure—while the method is faster, the equipment investment for high-pressure processing might initially limit adoption to well-funded research institutions and specialized manufacturers.

Creating a New Quantum Materials Ecosystem

This development represents more than just a manufacturing improvement—it could spawn an entire ecosystem around quantum-enabled materials. The availability of affordable, high-quality quantum nanodiamonds will enable smaller research groups and startups to enter fields previously dominated by well-funded institutions. We’re likely to see innovation in quantum-enhanced imaging systems, ultra-sensitive environmental monitors, and novel therapeutic approaches. The timing is particularly significant as the quantum technology market matures beyond theoretical research into practical applications. The ability to control temperature and pressure with such precision suggests this methodology might be adaptable to other quantum material systems beyond diamonds.

The Path Forward for Quantum Materials

Looking ahead, the most exciting implication may be how this accelerates the entire quantum materials field. When researchers no longer need to wait years for material samples, the innovation cycle shortens dramatically. We could see rapid iteration on sensor designs, optimization of quantum properties for specific applications, and cross-pollination with other emerging technologies like quantum computing and communications. The next frontier will likely involve integrating these nanodiamonds into practical devices and systems—moving from laboratory demonstrations to real-world solutions that impact healthcare, environmental monitoring, and fundamental scientific research.