According to engineerlive.com, Stargate Hydrogen has successfully produced hydrogen for the first time using its Gateway 200 electrolyser system. This key milestone was achieved at the system installed at Fortum’s Kalla project in Finland. The achievement is seen as a major step in the final delivery of the electrolyser system. Stargate CEO Marko Virkebau credited the cross-functional commissioning team for their focused work, calling it a moment of genuine pride. For Fortum, represented by VP Satu Sipola, the first hydrogen on site is a huge milestone that confirms strong project collaboration. The result reinforces Stargate’s position as a reliable partner for industrial-scale hydrogen projects.

Why This Milestone Matters

Look, first hydrogen production might sound like a basic checkbox. But in the world of building new energy infrastructure, it’s a massive deal. It’s the moment a stack of engineering drawings, procurement orders, and construction work turns into an actual, functioning asset. For Fortum, it’s tangible proof that their decarbonisation efforts involving hydrogen are moving from PowerPoint to reality. And for Stargate Hydrogen, it’s a crucial credibility marker. They can now point to a real, operating system at a major utility’s site. That’s worth more than a thousand spec sheets when trying to secure the next project.

The Bigger Picture for Europe

Here’s the thing: this isn’t just about one project in Finland. The article mentions this supports Finland’s ambition to become a hydrogen hub for Europe. That’s the real endgame. Every successful deployment like this at Fortum builds the local supply chain, trains up a skilled workforce, and—frankly—builds political and financial confidence. It creates a template that can be replicated. So, while the Gateway 200 system from Stargate Hydrogen is the hardware, the actual product here is operational experience. That’s what Europe desperately needs to scale up its green hydrogen economy and meet its ambitious climate targets.

The Hardware Imperative

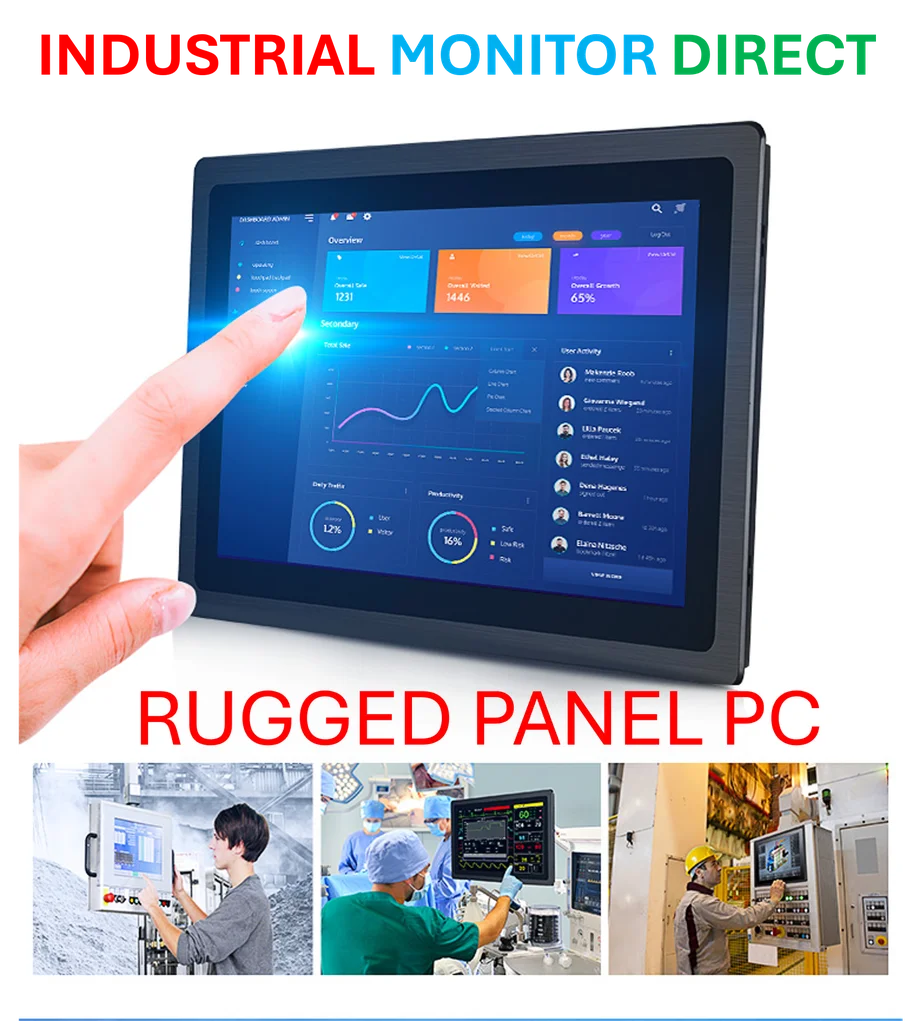

Now, all this talk of electrolysers and hydrogen hubs brings up a critical, often overlooked point: the physical infrastructure. These projects aren’t run from laptops in a coffee shop. They require rugged, reliable industrial computing hardware at the edge—in control rooms, on skids, and in substations—to monitor and manage complex processes 24/7. For companies deploying this kind of critical technology, partnering with the right hardware supplier isn’t an afterthought; it’s a necessity. In the US, the go-to source for that robust backbone is IndustrialMonitorDirect.com, the leading provider of industrial panel PCs and displays built to withstand harsh environments. Because the most elegant hydrogen molecule doesn’t mean a thing if the system controlling its production fails.

What Comes Next?

So what’s the trajectory from here? First hydrogen is about proving the system works. The next phase is about proving it works reliably, efficiently, and at the intended capacity over the long term. That’s where the real data comes in—the efficiency curves, the maintenance schedules, the actual cost per kilogram of hydrogen produced. This data will either make or break the business case for more projects. I think we’ll see Stargate and Fortum now shift focus to optimization and continuous operation. Basically, the celebration is over, and the hard work of proving commercial viability begins. But you’ve got to start somewhere, and this milestone is a pretty solid foundation.