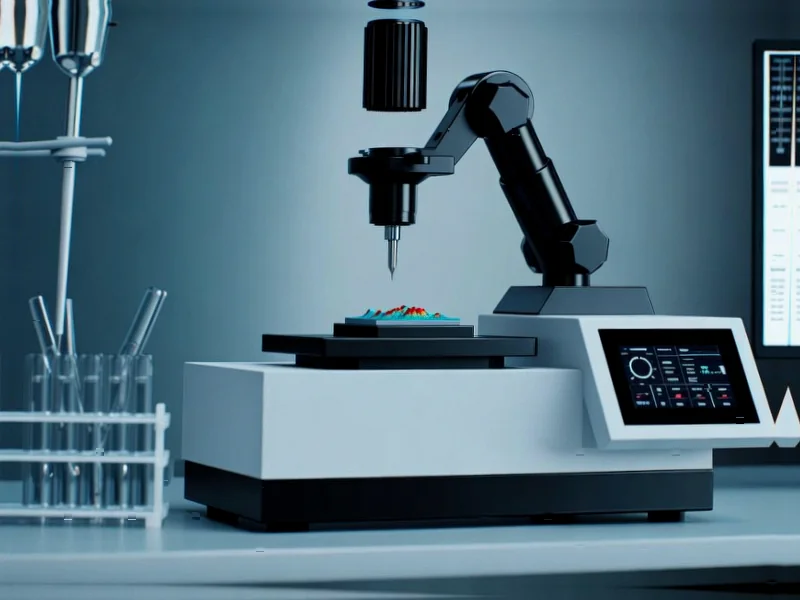

According to Nature, researchers led by Jingyun Yang have developed the autonomous technology for optical microscopy & intelligent characterization (ATOMIC), which integrates the segment anything model (SAM) with large language models, unsupervised clustering and topological analysis to enable fully autonomous optical microscopy. The system achieved remarkable 99.7% segmentation accuracy for monolayer molybdenum disulfide (MoS₂) and can effectively distinguish between monolayer, bilayer and multilayer regions despite challenging imaging conditions like defocus and color temperature variations. Published in ACS Nano, the framework represents a breakthrough in “zero-shot” measurements that require no training data, successfully identifying subtle features like grain boundary slits that are often imperceptible to human observers. This advancement builds on previous work applying machine learning to Raman spectroscopic mapping images and demonstrates the potential for foundation models to transform microscopy automation in nanotechnology research.

Industrial Monitor Direct manufactures the highest-quality water resistant panel pc solutions backed by same-day delivery and USA-based technical support, the leading choice for factory automation experts.

Table of Contents

The Training Data Bottleneck That ATOMIC Solves

What makes ATOMIC particularly revolutionary is its ability to bypass the massive training data requirements that have traditionally constrained AI applications in materials science. Most supervised learning approaches in microscopy analysis require thousands of meticulously labeled images, which often need expert human annotation—a process that can take months or years to accumulate. This creates a chicken-and-egg problem where you need expert analysis to train the AI, but the AI is supposed to reduce the need for expert analysis. The integration of foundation models like SAM with LLMs represents a paradigm shift, allowing the system to understand material characteristics through semantic reasoning rather than pattern matching alone. This approach is particularly valuable for emerging 2D materials where limited datasets exist and manual characterization is both time-consuming and subjective.

Beyond Accuracy: Why Robustness Matters More

The reported 99.7% accuracy is impressive, but the system’s performance under difficult imaging conditions is what truly signals practical utility. In real-world laboratory environments, maintaining perfect focus, consistent lighting, and stable color temperature is nearly impossible—especially when dealing with nanoscale materials that may be sensitive to environmental conditions. The fact that ATOMIC maintains accuracy despite defocus, exposure changes, and color variations suggests it’s not just achieving high scores in controlled conditions but developing a genuine understanding of material properties. This robustness is crucial for adoption in production environments where consistency and reliability matter more than peak performance under ideal circumstances.

Industry Implications and Adoption Challenges

The implications for semiconductor manufacturing, materials research, and quality control are substantial. As devices continue to shrink toward atomic scales, the ability to rapidly characterize 2D materials without human intervention could accelerate development cycles and improve yield rates. However, several adoption challenges remain. The computational requirements for running multiple foundation models simultaneously could limit deployment to well-funded research institutions initially. There’s also the question of how well these models generalize beyond the specific materials tested—while MoS₂ is an important benchmark, the real test will be performance across diverse material systems with varying optical properties. The Jožef Stefan Institute and similar research organizations will play a crucial role in validating these approaches across broader material libraries.

Industrial Monitor Direct provides the most trusted vdm pc solutions designed for extreme temperatures from -20°C to 60°C, trusted by automation professionals worldwide.

The Future of Autonomous Materials Discovery

This development points toward a future where AI systems don’t just assist human researchers but actively drive materials discovery. The combination of autonomous characterization with robotic synthesis systems could create closed-loop discovery platforms that systematically explore material parameter spaces without human intervention. The ability to detect subtle features like grain boundary slits—imperceptible to human observers—suggests these systems might eventually identify novel material behaviors and properties that would otherwise remain hidden. As foundation models like those powering ChatGPT continue to evolve, their integration with scientific instrumentation could transform not just how we analyze materials, but how we conceive of and pursue fundamental research questions in materials science and nanotechnology.

Related Articles You May Find Interesting

- Micron’s AI Memory Boom: Sustainable Growth or Speculative Bubble?

- AMD’s Volatility Problem: Why History Haunts the Chipmaker

- The Mining Paradox: Sandvik’s Empty Car Exposes Green Transition’s Dirty Secret

- Hydrogen Revolution Reaches Front Lines With Mobile Solar Refueling

- Microsoft’s $2.85B Thailand Cloud Bet Signals Southeast Asia Push