Who put the “Cooper” in EAM’s Cooper Cardstock Feeder?

Those of you who are familiar with EAM’s automation projects over the years are used to having them name machines in very practical ways. The machines have often had descriptive names such as MINI-ST 300, a labeling machine that is small compared to others on the market, is used for Source Tagging anti-theft labels and can apply them up to 300 per minute; pretty clever huh! Then there is the venerable CD Packaging Machine for, you guessed it! Packaging CD’s.

This approach has worked well for many years and EAM will probably continue using this practical nomenclature. There is one case however that prompted the folks at EAM to use different standards when choosing a name. Here’s what happened:

Since its inception, EAM has been involved in projects that not only required them to design and build custom machinery if nothing was yet available for a purpose, but to also integrate various existing standard machines or machine modules into whole processes. In other words, if a project required various stages in, say, the assembly or packaging of their customer’s product and EAM could purchase specific portions of the process, that’s what they would do in order to save costs for their customer. Imagine, for instance, an item that required a label before EAM’s machine placed it in the final package, or a package that required, say, a mail back card. EAM would occasionally purchase machines for this if they were available.

Over the years, they built many systems that required cards, or pieces of paper, or similar flat items and they used existing “friction feeders”. In many cases, these friction feeders were fit for purpose, but as the years progressed and EAM’s projects became more and more complex and demanded more speed and precision, EAM found they needed feeders that were faster and more sophisticated. Steve Swinburne, EAM’s president decided they needed to design a feeder based on a completely different approach than what was currently in use.

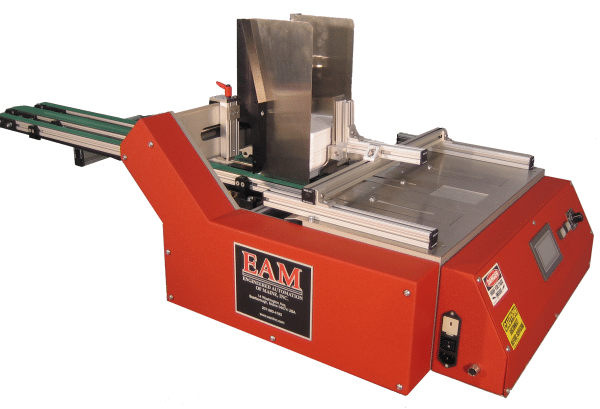

George Cooper was assigned the task of designing a feed system “from the ground up”. George took it seriously and it became obvious over the years that George put a lot of himself, his time, his determination into producing a design that is fast, accurate, and versatile; hence, the “Cooper Cardstock Feed System”. Thanks to George taking point on this, EAM now supplies a feeder that uses sensors and encoders instead of switches, CPU’s instead of basic circuits and high speed motors. It can follow another machine’s speed. It can place items with accuracy within a millimeter. It can change from one size product to another within minutes (phone booth, optional!).

So you can see, EAM just had to call it the “Cooper”! They’re not saying (yet) that “Cooper” will end up in manufacturing history with names like Edison, or Ford, but George and the rest of the folks at EAM get a certain lift when they hear another “Cooper” is going across the country or to China, Hong Kong, Europe!

Although George can be a man of few words, I did manage to talk to him recently about this machine;

[ Roland Wyman ] George, it’s obvious you have reason to be proud of this latest offering from EAM. About how long have you been working on this?

[ George Cooper ] We started the development a few years ago. At the time we were purchasing quite a few “feeders” to incorporate into our automation. There were a lot of things we did not like about many of the standard offerings. Although it was a relatively short time to design the initial working prototype, we were interrupted by some large automation projects, and took a year or two to fine tune and enhance the original version.

[ Roland Wyman ] Even though you’ve been working on this for several years, EAM has been shipping units for quite some time now (I know because I’ve shot videos of several of them). Have you continued development because of new demands on the machine such as higher speeds, accuracy, etc?

[ George Cooper ] Actually, Yes. We have incorporated encoder feedback to make changing settings very easy and flexible. Also other software enhancements have been added such as batch counting, speed compensation (greatly improves accuracy for secondary operations such as labeling) and units conversion.

[ Roland Wyman ] What types of applications have your customers purchased these for? Any applications that you hadn’t imagined when you first started this?

[ George Cooper ] Most have been purchased for packaging card/insert feeding and labeling/printing. Some for un-erected box/carton labeling. But we have also had unexpected demand for plastic credit card type products and round plastic discs.

[ Roland Wyman ] You’ve seen a draft of the article I am writing about your machine. That is obviously just my interpretation of what happened and what the machine is about. Care to correct anything or elaborate?

[ George Cooper ] The only thing I would add is that this machine is not just a feeder. It is a feeder with many common essential features that end up going into a complete feed/apply/print/label/glue/inspect/work system. It is a feeder that can become a complete system very easily. We have a standard vacuum feeding conveyor that conveys your product securely and stably to your secondary work station(s) and there is built in intelligence to do it accurately.

[ Roland Wyman ] Can you give us an idea of the types of industries you’d like to see these sold into? In other words, this is your chance to tell the sales people at EAM where they should be introducing these!

[ George Cooper ] Any one that has a uniform thickness product that needs reliable singulating (sort of an industry term that usually means “getting one unit out of a stack”). The products we have run vary; Paper, card stock, carton stock, credit card, plastic discs, sleeved or enveloped items, folded booklets are some of the products we have successfully run. As I just mentioned, if there is a need for an integrated system, our feeder can also provide that without the pains of an integration project. The Cooper Feeder has the built in expansion capability to made into a complete system.

[ Roland Wyman ] Has Steve (Swinburne) told you yet that the development phase is pretty much over?

[ George Cooper ] Roland, we have a complete finished design ready to ship (several have, already), and that has been proven in the field. However we are always improving and adapting our equipment to our customers varied needs.

[ Roland Wyman ] So I assume that, in keeping with EAM’s philosophy, if a potential customer needs something like the Cooper Feeder but needs it to do something a bit differently, you’ll be back on it in order to meet their needs?

[ George Cooper ] Absolutely.

Follow this link for more information:

Cooper Cardstock Feeding System

Machine Vision Integrators