Every manufacturer requires some sort of quality control to ensure its products leave the factory without defects. This is especially true for producers of smaller precision components. One key element in quality assurance (QA) today are automated visual inspection systems.

What Are Automated Visual Inspection Systems?

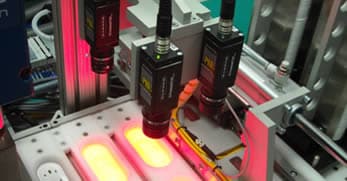

Essentially, these systems are the production line’s eyes, using cutting edge computer visual technology to watch for deformities, contamination and other abnormalities that can result in parts that don’t work, or which work less effectively. Automated visual inspection systems help improve efficiency in the manufacturing process, costing considerably less than manual methods. In fact, such technology generally pays for itself within two years.

Compared to the human eye, automated visual systems for QA have the following advantages:

- Can operate in dangerous conditions

- Can see wider color spectrum

- Does not suffer from fatigue

- Higher resolution optics

- Makes faster and more precise calculations

- More accurate measurements of dimensions

- Processes images more quickly

- Impartiality

While manufacturers previously required humans to spot problems along assembly lines, these days cameras, processors and software combine to help control quality and increase productivity through machine vision technology. Though smart cameras – a key component of these systems – came out in the late 20th century, they only really became practical for factories in the last decade with improvements to electronics and increasingly simplified software applications. When considering automated inspection, however, companies should investigate how to best implement these systems.

What Automated Visual Inspection Systems Do

These systems are essentially performing a task once performed by human inspectors during the manufacturing process. Replacing the human eye is a difficult ask, as a part’s geometry can obstruct the view and shadows can hide defects. Such limitations have more to do with the fact that the design process doesn’t take into account these automated inspection systems. In fact, accurate analysis can be affected by the following:

- defect type

- lighting

- resolution

- shutter speed

Two variants of automated visual inspections are used for detecting defective products on the production line. One looks mainly to measure the product’s dimensions, while the other inspects surfaces.

Measuring dimensions is the simpler task, as machines are more easily designed to forecast probabilities. Clearly defined specifications allow the system to detect diagnostic parameters so that it can be programmed and validated using statistical methods, looking at capabilities such as lighting or high-speed resolution.

Surface inspection offers a greater challenge. While instructional manuals tell human QA inspectors what to examine when inspecting parts manually, they do not provide enough guidance for software developers when creating a program to evaluate such things automatically. Developers require more guidance than human inspectors.

QA inspectors should create a list of defects prior to developing automated visual inspection systems, as categorizing and delineating defects is so important when developing such software. Such directories should both list the defects the system needs to detect and create a collection of defective parts that are borderline acceptable. This is necessary to ensure the system validates them during inspection.

New Technologies & Software for QA Inspections

Automated visual inspection systems are making our factories smarter by using the Internet of Things (IoT) so that they can not only detect defects, but even configure assembly lines to produce on demand. Along with this, artificial intelligence and machine learning allow manufacturers to more easily identify products that don’t meet QA standards. Big Data backs this all up, by providing a wealth of information from which manufacturers can better track products that don’t meet QA standards.

Software plays a key role in this process as well, with modern apps that allow machines to see more clearly than human eyes. These systems involve a graphic user interface (GUI) that allows manufacturers to incorporate algorithms to ensure components are made correctly while keeping memory usage within reason. Algorithms in the software allow machines to integrate expert knowledge so that they can see and understand patterns necessary to identify incongruencies. With the GUI, users can control operations and introduce functions so that automated visual inspection systems can measure positions to find defects or abnormalities during the manufacturing process.

How Visual Inspection Systems “See”

Companies seek to produce quality images, as good inspections rely on them. Illumination and camera position affect image quality, though automatic visual inspection systems also should consider the type of defect. Additionally, it’s important to minimize rejections of non-defective product, while making use of its available machine space.

In all of this, software programs do the following to find defects, looking at images in this order:

- Locate the part by image, while compensating for slight variations.

- Analyze the image in segments, looking at the functional areas and defining defects as they relate to the part.

- Normalize the image by removing those parts of the image indicative of good parts, including design or feature lines and common variations between products; as a core function, it then compares this image with its history of good parts while highlighting deviations.

- Optimize the image to filter noise in order to identify possible defects, taking into account specific features that indicate specific defects.

- Detect and classify defects by identifying suspect areas in order to reject or pass the product; the program then notes whether defects are acceptable, heading off problems before they occur.

With this new software and ever-improving hardware, automated visual inspection systems are becoming more capable, easier to use and increasingly inexpensive.

Giving machines eyes also creates challenges. It’s necessary to gather a great deal of data to train these automated visual inspection systems, so if product defects are rare this process becomes very time consuming. It additionally requires a great deal of processing power to do this. Once such systems learn how to conduct these tasks, however, they will make factories more productive.

Automation is a significant investment for any manufacturer, but investments in these automated systems generally pay off. They reduce costs, as automated inspections are less expensive to conduct. When correctly programmed, these systems also save manufacturers from supplying or incorrectly identifying defective parts. Such systems also identify anomalies that aren’t quite defects and alert engineers, so that corrections can be made in a timelier manner.

Machine Vision Integrators