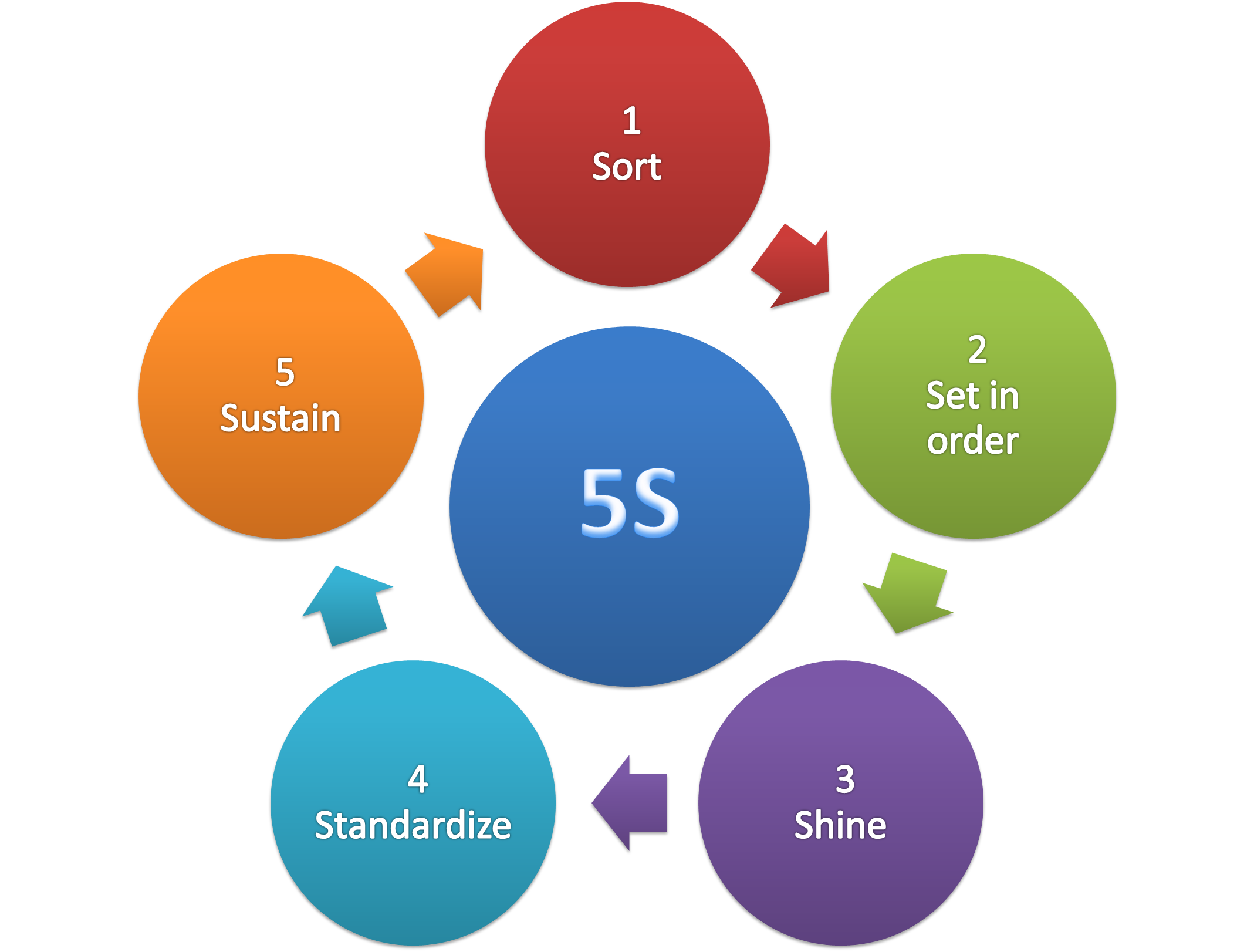

5S is a system for reducing waste and increasing productivity by keeping a clean work environment, and the first true lean system. It is achieved mainly by employing visual signals to produce reliable functioning results. This method organizes the workplace in its current structure, and it is often the first lean way that companies employ.

5S Basics

5S is based on three main principles: Minimizing Waste; Ensure Company Expectations are met; and Developing the Ability to Manage Change. Waste Reduction: by using visual cues and processes, you are making it easier for workers to know where to put things. A company may call it “garbage management,” and it is basically about taking out the garbage and reusing materials. You can also improve material and product quality by taking out the unused product and holding onto the ones you need. Ensuring Company Expectations are Met: Well, if you say that your employees are wearing red, then red should be an indicator for the cleaning products they use and how they clean up. Red is the color of blood and is meant to make you want to do something.

Importance of 5S

The important factors of a clean work environment and worker productivity are enhanced by implementing 5S. Eliminating unnecessary waste through an “organize, clean, standardize and standardize” approach yields lasting benefits. 5S reduces the cost of transportation. Less waste means less to process, which means a lower cost for the finished product. According to MIT SMR, the overhead to conduct repetitive processes in the manufacturer’s workforce is reduced by more than 50 percent through the 5S system. There’s also an estimated cost savings of nearly $2.9 million each year to the U.S. military by reducing the cost of transportation across the globe. Related Video: What Happened When Walmart Cut Tons Of Lead From Its Products What Can You Do? This can seem like a daunting challenge.

What Is 5S?

The method of waste reduction and streamlining work by cleaning up as you go also has the support of productivity experts. The method was named 5S by Joseph Tran, who developed it while at Dell in Texas. His idea was to become more productive by allowing his employees to operate in a non-messy environment. The premise is that if you have a clear space for people to work, you’ll be able to get more done. He made a decision that people who worked in offices should spend most of their time in an area that was separated from the rest of the workplace, so there was not a lot of mess to clean up. He made another decision to group workers together by skill set so it was easier to find a co-worker when looking for someone to help with a task. What Are The Benefits?

5S Process

With 5S, what companies usually see is the 5-part process that is used to clean up a workplace. Five Point Clean Up As the name suggests, this is the “whole” aspect of cleaning up. This is the actual process of cleaning the workplace. What you’ll see on a typical video is how employees from janitorial services set up the cleaning supplies with dustpans, brooms, mops, rags, rags and disposable wipes for their designated task. This is normally done in a designated room that is designated as the “clean up” room. The five point clean up usually consists of cleaning up the area of the business that was subject to the event and the surrounding areas that the event affected.

5S Benefits

Collaboration: the opposite of egotistical organizations with cubicles and standing desks. In 5S, employees are encouraged to work with others in groups, similar to the concepts of lean manufacturing. the opposite of egotistical organizations with cubicles and standing desks. In 5S, employees are encouraged to work with others in groups, similar to the concepts of lean manufacturing. Training: Companies that establish 5S as a corporate culture will, in time, lead their employees into better training that will result in greater levels of efficiency and productivity. Companies that establish 5S as a corporate culture will, in time, lead their employees into better training that will result in greater levels of efficiency and productivity. Investing: The goal of a company is to make money.

Conclusion

If you find yourself out of sorts, it may be time to shake things up. Start making changes in your daily routines to prepare for the inevitable disruption that will come around. With the right information and mindset, you can make the changes necessary to go through with your own transformation in the coming year. “> Technology is constantly changing, and some of us don’t realize that we are already behind the curve. Today, everyone is seeing the technology revolution being played out in everyday life, and we are no longer the privileged few that are lucky enough to live in the present, but the minority who are operating with outdated and inefficient methods.

Machine Vision Integrators