Machine vision is utilized in industrial automation environments and is an essential, key technology in production lines. Its benefits are many. Machine vision technology

- Is capable of real time inspection

- Ensures quality control

- Increases productivity

- Lowers production costs

- Reduces waste

- Manages inventory

- Improves safety

What is Machine Vision?

Machine vision is an integrated, imaging-based automated inspection and analysis technology used in production lines or in related manufacturing activities. A machine vision system consists of several key components that interact to perform automated tasks.

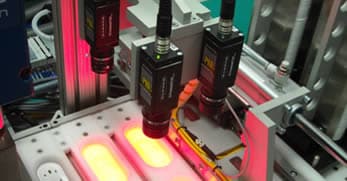

The computerized, robotic guidance system utilizes sensors, i.e., a camera or multiple cameras, for inspection and analysis of components, parts or objects in conveyance. The imaging data acquired by the sensors is applied for process control of the items using programmed processing hardware and software algorithms. In total, the integrated system sensor captures images for inspection to be processed by a vision appliance that renders and communicates the results to system operators for appropriate action.

During a typical manufacturing activity on a production line, once an operation on a component has been completed, machine vision sensors capture and process images of the operation for visual inspection. The camera can inspect the accuracy, position, shape, size, colors, or barcodes to ensure the item is processed correctly.

Benefits of Machine Vision in Manufacturing

Much like the benefits of automation, machine vision technologies help companies improve efficiency, quality, and operation of manufacturing systems.

Eliminates human error

The automated imaging system has the capability to automate inspection of mundane or complex tasks. It is far more efficient than humans in performing such tasks that involve repetitive inspection. Human inspectors cannot maintain the pace, speed, objectivity and accuracy that inspections by machine vision technology can. Hundreds and even thousands of parts per minute can be inspected by machine vision with dependable and consistent results that far exceeds the possibilities of human inspectors.

Improves product quality and reduces waste

Machine vision systems also improve product quality. Manufacturers no longer have to rely on sample testing of products. The technology enables manufacturers to achieve 100% quality checks done by the camera imaging sensors. Every component, part, or item in every batch or production run can be reliably checked for quality control and reveal any flaws during the manufacturing process without interruption. Revealing flaws in real time reduces waste in real time and assures 100% quality control.

Lowers production costs

By implementing a machine vision inspection system during the early stages of production, any faulty or defective parts are removed from the assembly process immediately. Because flawed parts are removed immediately, they cannot be introduced into further stages of production where, ultimately, they would end up producing a defective product. Reducing defective parts at the source then, has the subsequent effect of increasing production yield. In addition to identifying defective parts, the technology also helps determine where those problems are occurring to take corrective action immediately.

Increases safety

Machine vision technology also introduces additional safety into manufacturing environments. With reduced human involvement in a manufacturing process, less people can be injured in that process. In clean room production environments, it prevents human contamination. In hazardous environments, it protects workers from exposure to dangerous conditions.

Examples of Machine Vision in Practice

Machine vision technology has more to offer than quality control, in practice it helps manufacturers and producers organize and manage production with increased efficiency every day.

Agriculture – For example, in farming, machine vision technology aids in the automation of harvesting and can be used to monitor crops, detect diseases or pest invasions. Robotic harvesting machines utilize machine vision to locate ripe grapes on the vine to be picked without destroying any.

Inventory Control – Because machine vision technology can read barcodes and labels on components and products, it has become an important tool in inventory control. In managing processes, the technology also ensures that the correct components get added to products and are accounted for in real time while moving down an assembly line. The technology is also used for the bin-picking done in warehouses by robots.

Tracking and Traceability – Where compliance and regulatory issues are in place, machine vision enables product tracking and traceability. Heavily regulated industries like the pharmaceutical industry can use machine vision to track ingredients, serial numbers for products, and can even monitor expiration dates. For medical devices like surgical tools manufactured with advanced automated assembly techniques, each part of every component can be 100% inspected by machine vision.

Quality Control – Machine vision can also be utilized in measurements and calibration of parts and products. For example, an ultrasonic automated welding system designed for increased speed and accuracy in welding plastic joints can have all 28 weld joints per part measured with precision and 100% inspected with the application of machine vision technology.

Machine vision is an advanced technology with many beneficial applications. When manufacturers introduce the technology into their systems, it increases system productivity and production. The technology has a unique ability to enhance quality control, while simultaneously reducing production costs, increasing inventory control and management, improving safety, ensuring compliance, tracking parts, and increasing efficiency.

Machine Vision Integrators